-

Product index

Click on the articles to move on the page

- Tungsten carbide cutting tools

- Tungsten Sintered Bars

- Tungsten SIntered Plates

- Tungsten Square Bars

- Tungsten Rods

- Tungsten Wires

- Tungsten-Base Heavy Alloy

- Tungsten Copper Alloy

- Tungsten Rhenium Alloy

- Tungsten Sheets

- Tungsten crucibles (2 Types)

- Tungsten Contacts

- Molybdenum Evaporation Boats

- Other Products of Tungsten

-

Tungsten

Tungsten, also known as wolfram, is a lustrous, silvery-white metal that tarnishes in air. It has the highest melting point of all other non-alloyed metals. It also has the highest tensile strength. Pure tungsten is ductile; however, impure tungsten is often brittle and hard making it difficult to work with. It is one of the five major refractory metals, meaning that it is has a very high resistance to heat and water. Its atomic number is 74 and the chemical symbol for is W.

ShaanXi's tungsten products can be produced according to the requests of customers: tungsten bar, tungsten sheet, tungsten wire, tungsten disc, tungsten crucible, tungsten carbide and other tungsten compounds.

-

Applications

Due to its hardness, tungsten is used in of heavy metal alloys. It is also used in military applications, and can be found in penetrating projectiles. A significant amount of tungsten, approximately 18%, is used in making high speed steel (steel that can cut through materials at higher speeds than carbon steel). Tungsten carbide, due to its hardness, makes it a key component in tools. Tungsten’s high melting point lends its properties to the aerospace industry for high-temperature applications such as electrical, heating and welding applications. It is also used in jewelry due to its wear resistance.

Pure tungsten is used mainly in electrical applications, while tungsten compounds and alloys are used in various applications, most commonly in incandescent light bulb filaments, X-ray tubes (as both the filament and target), and superalloys.

Tungsten carbide cutting tools

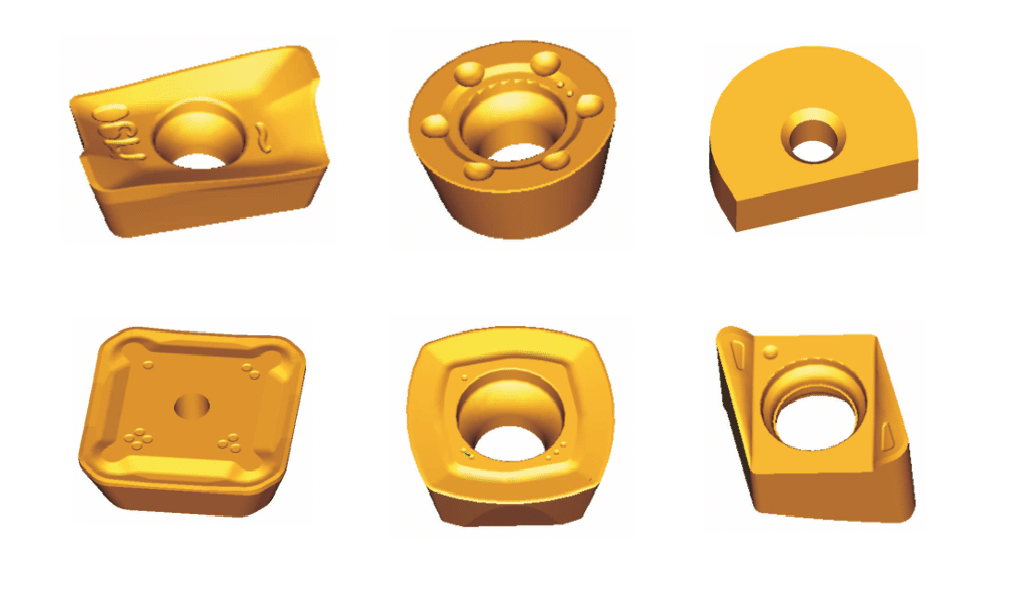

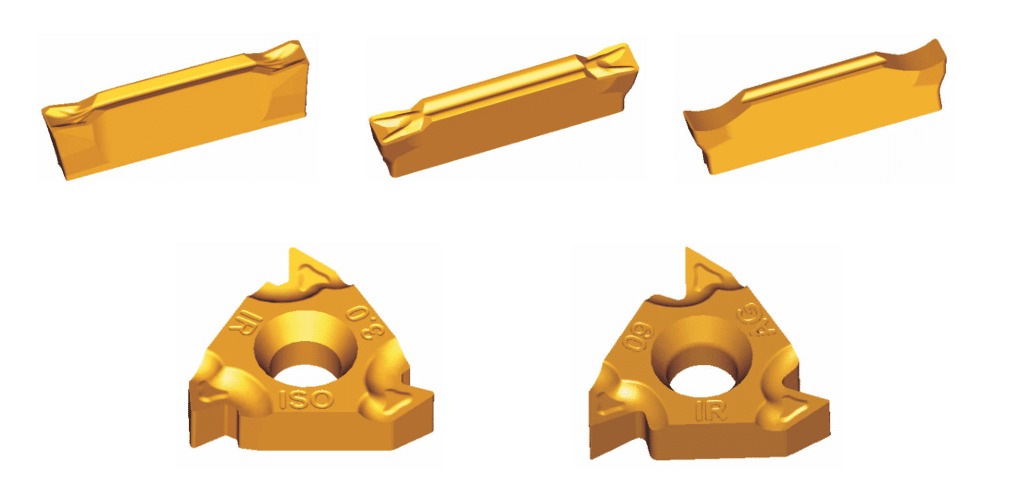

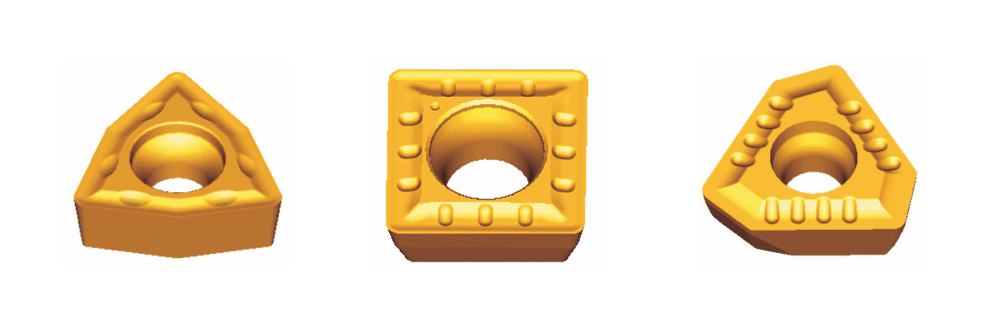

INDEXABLE INSERTS

New Catalogue of tungsten carbide cutting tools

DOWNLOAD

Examples of our new range of indexable inserts for tungsten carbide cutting tools

Shaanxi Yi Heng is a leading supplier of high-performance cemented carbide (tungsten carbide) cutting tool inserts. We are dedicated to empowering manufacturers worldwide by providing cutting-edge, reliable, and cost-effective solutions for the most demanding machining applications.

Leveraging deep expertise in advanced materials science, precision engineering, and cutting-edge coating technologies (including CVD, PVD, and specialized surface treatments), we design and produce a comprehensive range of inserts. Our portfolio encompasses geometries and grades optimized for:

* Turning, Milling, Grooving & Threading,drilling

* Roughing, Finishing & High-Speed Machining (HSM)

* Machining a vast array of materials: Steel, Stainless Steel, Cast Iron, Superalloys, Non-Ferrous Metals, Composites, and more.

Every ShaanXi Yi Heng's insert is manufactured under stringent quality control standards using state-of-the-art CNC grinding and coating facilities.

Supported by our global network and dedicated technical service team, we provide application-specific solutions and expert guidance. Partner with Shaanxi Yi Heng Non-Ferrous Metals Industries Co., Ltd to experience the difference that precision-engineered cemented carbide inserts make in boosting your machining efficiency, quality, and profitability.

Indexable Inserts

Tungsten Sintered Bars

Fabricadas a través de troquelado y CIP. Sinterización en horno de sinterización por inducción al vacío a temperatura entre 2000-2500 (2273-2773 K).Materiales: W (99.95% min.), W de aleación (WAL).Aplicación: para posterior procesado de productos semielaborados

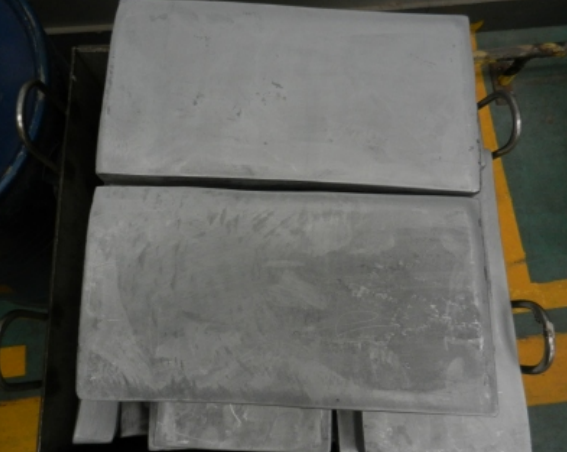

Tungsten Sintered Plates/Sheets

Manufactured through die pressing and CIP. Sintering in vacuum induction sintering surnace at temperature between 2000-2500℃(2273-2773K).

Materials: W (99.95% min.).

Application: For further processing to semi-finished products.

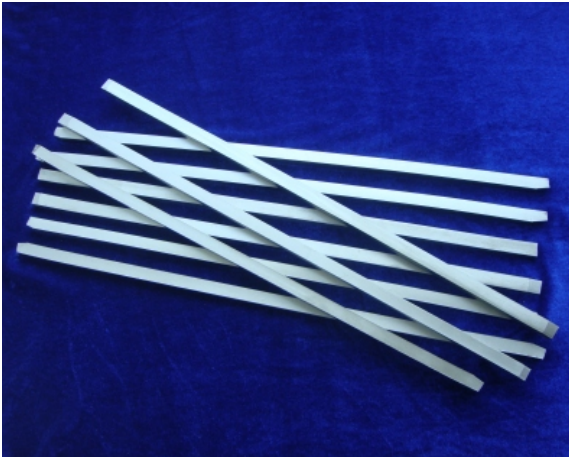

Tungsten Square Bars

Pressing in hydraulic presses with steel dies, pre-sintering in muffle furnace, then direct resistance sintering.

Materials: W (99.95% min.). W alloy (WAL).

Application: for forging or rolling to rods and wire drawing.

Tungsten Rods

The sintered bars are worked at temperatures up to 1600 (1873 K) using processes such as forging, rolling and swaging.

Materials: W (99.95% min.).

Divided coarse forged rods, smooth forged rods and ground rods.

Tungsten Wires

Wires are manufactured from round bars by drawing, annealed and with electropolished or pickled surface.

Materials: W (99.95% min.). W alloy (WAL).

Size: 0.012-1.8mm on spool.

Tungsten-Base Heavy Alloy

Material: W-Ni-Fe (Tungsten-Nickel-Iron), W-Ni-Cu (Tungsten-Nickel-Copper). Application: radiation protection materials, counterweight materials, inertia materials, dynamic equilibrium materials, kinetic energy materials, high temperature molds, etc.

Tungsten Copper Alloy

Our tungsten copper composites are used worldwide for electrical discharge machining (EDM) and electrochemical machining (ECM) electrodes. All composite material is manufactured by the press, sinter, and infiltrate process; adhering to strict quality checks every step of the way. You can rely on the quality of our tungsten composites to provide consistent, homogeneous materials that yield high and even burning rates.

Applications:

1. Arc contacts and vacuum contacts in high/medium voltage breakers or vacuum interruptors.

2. Electrodes in electric spark erosion (EDM) cutting machines.

3. Heat sinks for passive cooling of electronic devices.

4. Electrodes for resistance welding.

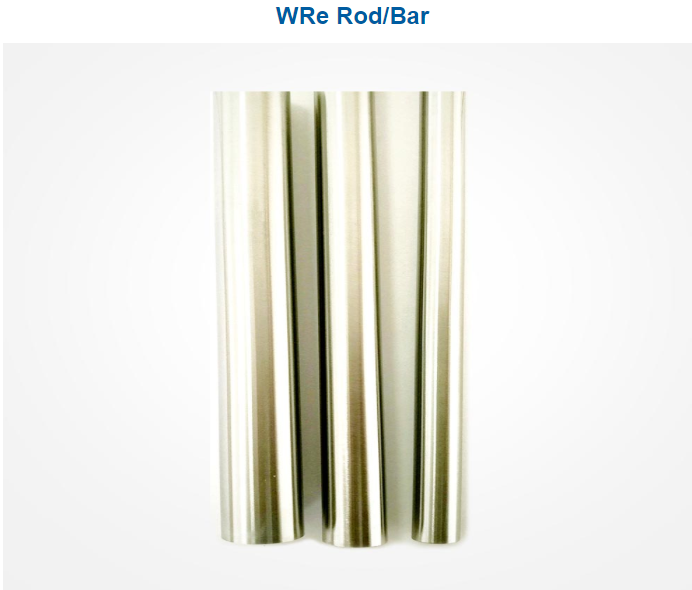

Tungsten Rhenium Alloy

Materials: W-Re alloys are made from Tungsten alloyed with3%,5%,25% or 26% Rhenium,which become more ductile and machineable .With good electrical properties,W-Re alloys are widely used as high temperature thermocouple materials.

| Product Name | Main Type | Main Spec.(mm) |

| WRe thermocouple wire | WRe3/25, WRe5/26 | φ0.1,φ0.2,φ0.25, φ0.3,φ0.35,φ0.5 |

| WRe alloy wire | WRe3%, WRe5%, WRe25%, WRe26% | φ0.1,φ0.2,φ0.25, φ0.3,φ0.35,φ0.5 |

| Sheathed WRe thermocouple | WRe3/25, WRe5/26 | Used in vacuum,hydrogen and inert gases with working temperature range of 0~2300℃ |

| WRe Rod/Bar | WRe3%, WRe5%, WRe25%, WRe26% | φ1-φ35 |

| WRe Alloy Sheet/Plate | WRe3%, WRe5%, WRe25%, WRe26% | 0.2minx (10-350) x600max. |

| WRe Alloy Target | WRe3%, WRe5%, WRe25%, WRe26% | Customized as per requirement |

| WRe Alloy Tube | WRe3%, WRe5%, WRe25%, WRe26% |

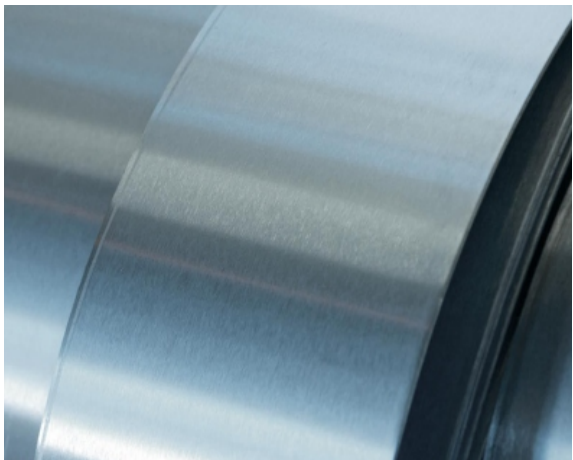

Tungsten Sheets

Divided cold rolled with bright surface and hot rolled with pickled surface.

Material: W (99.95% min.), W alloy.

Size: Thickness 0.2 mm min Width 350 mm max Length

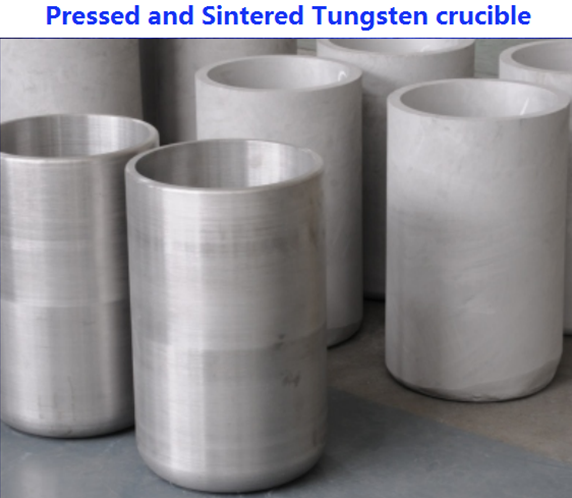

Tungsten crucibles (2 Types)

Application: For sapphire single crystal growth furnace.

1. Pressed and Sintered Tungsten crucible.

Powder is pressed and sintered to final shape geometries to meet the requirements of each furnace design.

2. Milled Tungsten Crucibles.

Material blanks are machined to the final product geometries.

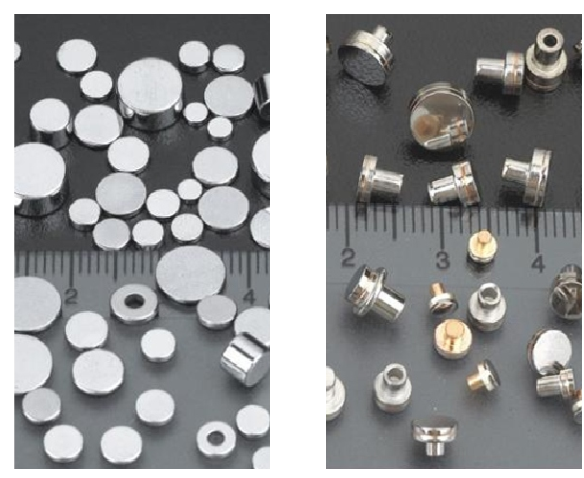

Tungsten Contacts

Material: W discs composited steel rivet by copper discs, W discs composited copper rivet by silver discs.

Model: flat, sphere, hole.

Application: auto horn, electric appliance.

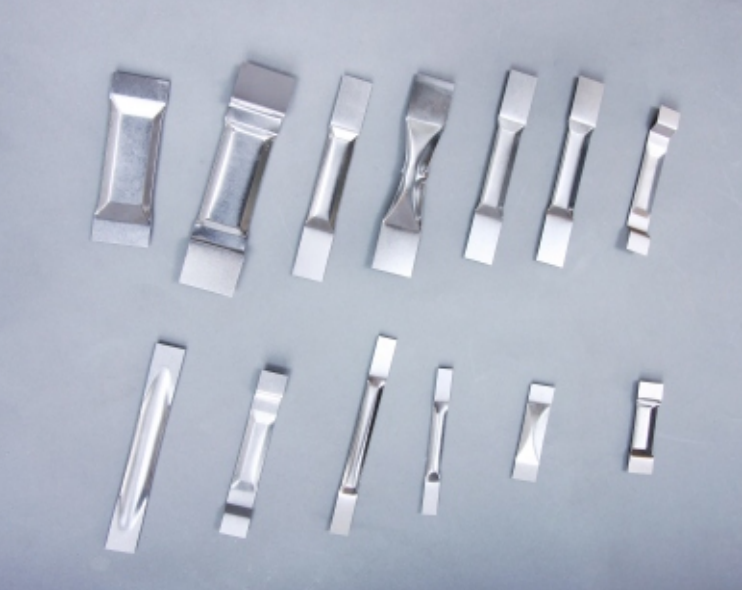

Molybdenum Evaporation Boats

Materials: Pure Tungsten (99.95% min)

Tungsten boat is made from Tungsten sheet through a process of cutting, bending, welding and riveting.

Applications:

Tungsten boat can be used in light, electronic and military industries. It can also be used as container for rare earth smelting.