-

Product index

Click on the articles to move on the page

- Molybdenum Sintered Plates

- Molybdenum Sintered Bars

- Molybdenum Square Bars

- Molybdenum Rods

- Molybdenum Wires

- Molybdenum Sheets/Foils/Ribbons

- Molybdenum Fabricated Products

- Molybdenum Glass Melting Electrodes (GME)

- Molybdenum Sputtering Targets (Planar & Rotary)

- Molybdenum Semiconductor Base Plates

- Molybdenum squares and rectangles

- Molybdenum Evaporation Boats

- Molybdenum Tubes

- Molybdenum Fasteners

-

Molydenum

Molybdenum is a silvery-white lustrous metal with reminiscent of tin. It has a density of 10.22 g/cm³ and is very much lighter when compared to tungsten, but with high boiling point of 5,560 °C and melting point of 2,620 °C.

It is a hard, tough and high strength material with low degree of thermal expansion, low heat resistance, and superior thermal conductivity. These properties make it the material of choice for applications that require high degree of heat protection and excellent thermal conductivity.

ShaanXi's molybdenum products can be produced according to the requests of customers on: bars, sheets, wires, discs, crucibles, molybdenum alloy (TZM alloy ) and any other fabricated molybdenum parts. -

Applications of Molybdenum

Molybdenum is a valuable alloying agent in various steels, as it not only contributes to their toughness, but also improves the corrosion resistance and weldability of the steels. Approximately 80% of this metal is used in the production of various steels, such as structural steels, stainless steels, high-speed steels, tool steels and so on. The rest of 20% of Mo products basically utilized in the electronics industry for thermal heat sinks and semiconductors thanks to its low degree of thermal expansion.Molybdenum furnace linings deliver high degree of protection against heat radiation in high-temperature furnaces and molybdenum crucibles are ideal for crystal growth in the production of LEDs. In the glass industry, glass melting electrodes fabricated from molybdenum are well suited for highly pure types of glass.

Molybdenum Sintered Plates

Pressing in hydraulic presses with steel dies, or pressing in CIP/HIP. Sintering in vacuum induction sintering furnace.

Materials: Mo (99.95% min.), Mo alloy (ML, TZM, MHC).

The slabs also can be produced by the EB (Electron Beam) melting process.

Material: Mo (99.97% min.).

Molybdenum Sintered Bars

Pressing in CIP or HIP. Sintering in vacuum induction sintering furnace.

Materials: Mo (99.95% min.), Mo alloy (ML, TZM, MHC).

The billets also can be produced by the EB (Electron Beam) melting process.

Material: Mo (99.97% min.).

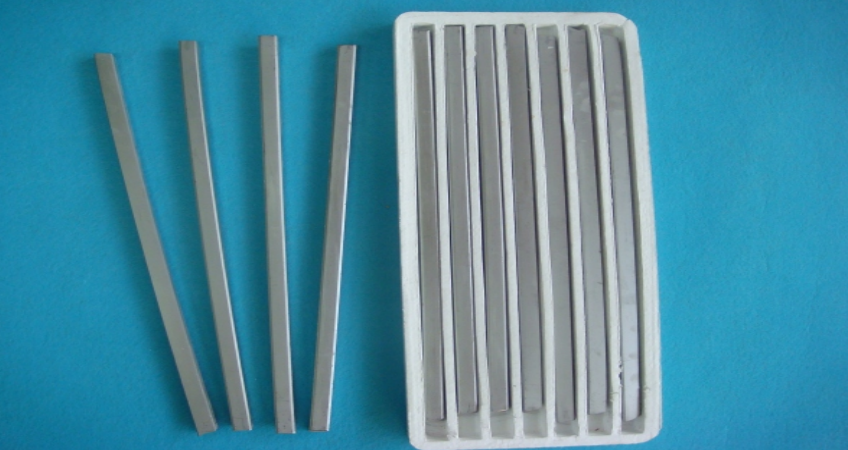

Molybdenum Square Bars

Pressing in hydraulic presses with steel dies, pre-sintering in muffle furnace, then direct resistance sintering.

Material: Mo (99.95min.).

Application: for further melting into high purity ingot, then forged and formed into the desired shape.

Molybdenum Rods

The sintered bars are worked at temperatures in the range 1200-1500 (1473 ~ 1773 K) using processes such as extrusion, forging or rolling.

Material: Mo (99.95% min.), Mo alloy (ML, TZM).

Standard: ASTM B387.

Divided coarse forged rods, smooth forged rods and ground rods.

Molybdenum Wires

Wires are manufactured from round bars by drawing, annealed and with electropolished or pickled surface.

Material: Mo (99.95% min.), Mo alloy (ML).

Standard: ASTM B387.

Application:

For lighting: 0.02- 0.35mm.

For MS-WEDM or HS-WEDM: 0.06- 0.35mm.

For magnetron: 1.0- 3.0mm.

For spraying: 1.0- 4.2mm.

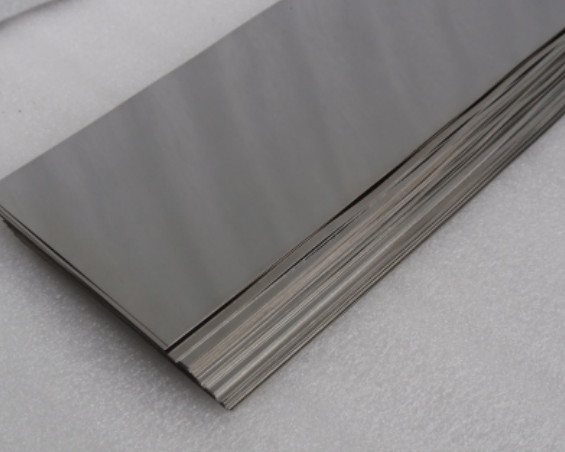

Molybdenum Sheets/Foils/Ribbons

Molybdenum Sheets

Divided cold rolled with bright surface and hot rolled with pickled surface.

Material: Mo (99.95% min.), Mo alloy (MLR, TZM, MHC).

Standard: ASTM B386.

Sheets made of pure molybdenum

0.1mm-40mm Width 610mm max Length.

Sheet quality: standard quality, deep drawing quality, furnace quality.

Sheets made of Titanium-Zirconium-Molybdenum (TZM)

Thickness 1.0mm-20mm x Width 500mm max x Length 1000mm max.

Molybdenum Foils / Ribbons

Rolled by 20-high cold rolling mill with very low production tolerances and guaranteed flawless surface.

Material: Mo (99.95% min.), Mo alloy (MLR, TZM, MHC).

Standard: ASTM B386.

Measurement: 0.025-0.13 mm (thickness) x 310 mm (width max.)

Molybdenum Fabricated Products

Molybdenum Crucibles (spun-pressed sintered)

Application: for sapphire single crystal growth furnace, quartz &glass smelting container and rare earth smelting container.

Molybdenum Glass Melting Electrodes (GME)

GME manufactured from Powder Metallurgical Processing or EB (Electron Beam).

Melting Process:

1. Standard or tapered threads

2. Machined or centerless ground surfaces for assurance of

concentricity and straightness

3. High purity (99.95% min.)

4. Bubble free, low carbon electrodes

5. GME from 1.25" (31.75 mm) to 4" (101.20 mm) in diameter

6. Uniform recrystallized grains for creep resistance

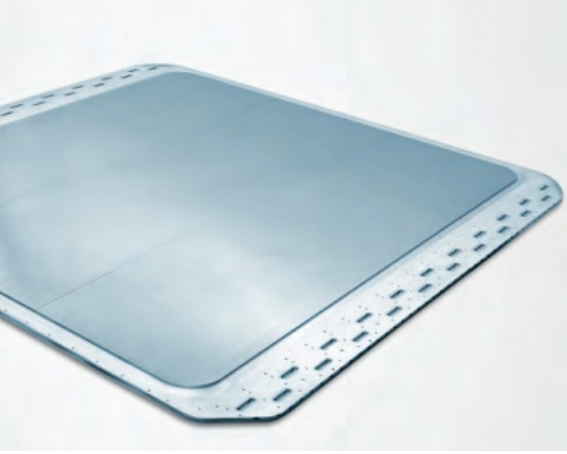

Molybdenum Sputtering Targets (Planar & Rotary)

Application: flat panel displays, thin-film solar cells and coatings.

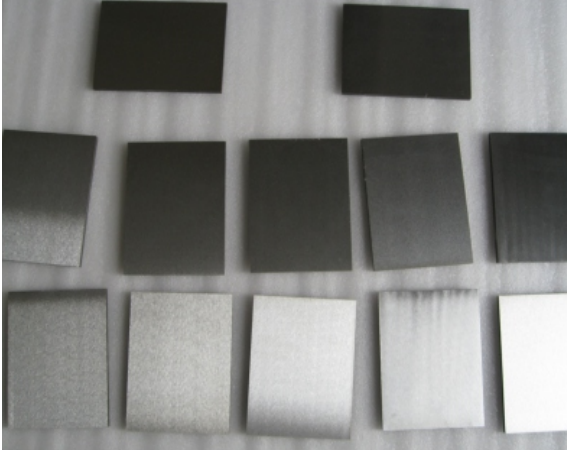

Molybdenum Semiconductor Base Plates

Plates manufactured by Japanese Speed Fam 16B high-precision

lapping machine with the excellent flatness.

Size: Diameter 3.5mm-150mm x Thickness 0.1mm-6.0mm.

Molybdenum squares and rectangles

Size: Thickness 0.1mm-5.0mm x Width 2mm-10mm x Length 2mm-100mm.

Molybdenum Evaporation Boats

We can provide bending, folding, riveting, pressing and welding molybdenum boats according to our customer’s requirements.

Molybdenum Tubes

Manufactured by spun-pressed sintered or normal sintered.

Measurement: External diameter 4.0-10 mm , Wall 1.0-1.5 mm, length 1000 mm

Molybdenum Fasteners

Manufactured by molybdenum bar and plate.

Standard: DIN, ISO, ASME/ANSI