-

Product index

Click on the articles to move on the page

-

Titanium

It is a metal group of transition elements, silver white, very light and resistant, extracted from rutile; is used in metal alloys as a substitute for aluminium for the manufacture of aircraft, missiles, space capsules, as a substitute for bones and cartilage in surgery, for the manufacture of pipes and desalination plants, etc.

-

Characteristics

The physical characteristics of titanium are as follows:

It’s a transition metal.

Its density is 4'54 g/cm3.

It has a melting point of 1668 ºC.

Its atomic mass is 47.867 u.

It’s a silver-gray color.

It is paramagnetic, that is, not magnetized due to its electronic structure.

Form alloys with other elements to improve mechanical performance.

Resistant to corrosion.

Refractory.

Low thermal and electrical conductivity: It is not a good conductor of heat or electricity.

Titanium ingots

Titanium ingot was melted by VAR or EB furnace with high purity and low inclusion, after chemical and non-destructive test they were sawed into certain length for subsequent forging or rolling, or integrally packed for sale after stringent inspection and surface finishing.

Size: diameter 200 mm – 1060 mm.

Weight: 500 kg – 12000 kg.

Standard: GB/T, GJB, ASTM, AMS, JIS. Customization is available.

Available grade: Gr1, Gr2, Gr3, Gr4, Gr5(Ti6Al4V), Gr7, Gr12, Gr23(Ti6Al-4VEli).

Source of raw materials: China, Russia, Ukraine.

Titanium bars

Titanium bars are forged by 3150T,1250T hydraulic forging press or GFM precision forging Machine, and further to be rolled and machined.

Chemistry & Standard: ASTM B348, F67, F136, ASME SB348, AMS-4928, ISO5832-2, ISO 5832-3, AMS4911, AMS 4975.

Materials:

• Available grade CP Ti: Gr 1, Gr 2, Gr 3, Gr 4.

• Available grade Ti Alloy: Gr 5(Ti6Al-4V), Gr 7, Gr 9, Gr 12, Gr 23(Ti6Al-4VELI).

Size: 8 mm – 3000 mm.

Diameter tolerance: h8, h10, h11.

Titanium bar for additive manufacturing

(3D printing)

Application : Electrode induction melting gas atomization(EIGA)

Plasma rotating electrode process(PREP)

Standard :ASTM B348 ASTM F67,ISO5832-2, ASTM F136 ,ISO5832-3, ASTM F1295,ISO5832-11

Diameter :40-250mm

Length :500mm-4000mm

Materials Code :Gr1, Gr2,Gr5, BT20(Ti-6.5Al-2Zr-1Mo-1V), BT9(Ti-6.5Al-3.5Mo-1.5Zr0.3Si)

Titanium sheets/plates

Plates and sheets are rolled by 650mm, 1200mm, 3300mm hot and cold rolling mills.

Chemistry & Standard: ASTM B265, ASTM F67, ASTM F136, AMS4902, AMS4911.

Available grade: Gr 1, Gr 2, Gr 3, Gr 4, Gr 5 (Ti6Al4V), Gr 7, Gr 9, Gr 12, Gr 17, Gr 23.

Sizes:

Cold rolled: 0.5 mm - 5.0 mm (thickness) × 1500 mm max (width) × 3000 mm max (length).

Hot rolled: 5.0 mm -100 mm (thickness) × 2800 mm max (width) × 7000 mm max (length).

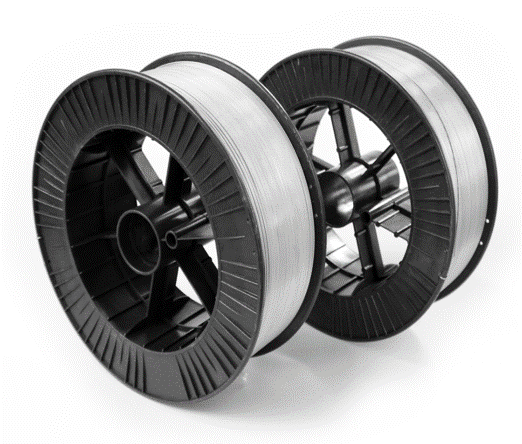

Titanium wire

Titanium wire is available in a spool, cut to length, coil or provided in full bar length. Our titanium welding wire fulfill AWS A5.16-2007 standard , ERTi-1,ERTi-2,ERTi-3,ERTi-4,ERTi-5,ERTi-7,ERTi-9,ERTi-10,ERTi-23 is flagship products which wildly used in aerospace, marine engineering ,defence project . Our Titanium wire also typically used in the chemical processing industry and anodized for hanging parts or components or when an item requires being tied down. Our Titanium wire is also great for racking systems that require strong materials.

Available standard: ASTM B863, ASTM B348, ASME SB348, AMS4951, AMS4954, AMS4956.

Available grade: Gr1, Gr2, Gr4, Gr5, Gr9, Gr11.

Diameter range: 0.5 mm - 6.0 mm.

Manufacturing technique: Cold Drawing (Cold-Drawn).

Titanium wire for additive manufacturing

(3D printing)

Application : WAAM&EBM

Standard :AMS4954

Diameter: 0.80mm, 1.0mm,1.2mm, 1.6mm(5-11Kg/Coil), 2.0-6.35mm(20-250Kg/Coil)

Materials Code: Gr1,Gr2,Gr5, BT20(Ti-6.5Al-2Zr-1Mo-1V), BT9(Ti-6.5Al-3.5Mo-1.5Zr0.3Si)

Titanium pipes and fittings

Titanium pipes and fittings are available in different sizes, length, forms and types in accordance with the various demands of the clients. These titanium fittings are known for their wonderful features like specific design, corrosion & abrasion resistance and durable finishes.

Product Forms:

45° Titanium Elbows, 90° Titanium Elbows, 180° Titanium Returns.

Titanium Equal Tees (Titanium straight tees), Titanium Reducing Tees.

Titanium Concentric Reducers, Titanium Eccentric Reducers.

Titanium Lap Joint Stub Ends.

Titanium Reducers.

Titanium Couplings.

Titanium Bushings.

Titanium Caps.

Titanium Pipe Nipples.

Titanium Pipe Plugs.

Remarks: Other materials and drawings are available.

Applications:

Titanium fittings serve as connectors for tubes and pipes, mainly applied to Electronic, Chemical industry, Mechanical equipments, Galvanizing apparatus, Environmental protection, Medical, Precision processing industry and so on.

Chemistry & Standard: ASME B16.9, ASTM B363, DIN 17861.

Materials: Gr 1, Gr 2, Gr 3, Gr 7, Gr 9, Gr 12, Gr 16, Gr 17.

Titanium tubes

Tubes and pipes manufactured by cold rolling process from extruded pipe and annealed in vacuum annealing furnace.

Chemistry & Standard: ASTM B338, ASME SB338, ASTM B861, ASME SB861, ASTM B862, ASME SB862, etc.

Materials: Gr 1, Gr 2, Gr 3, Gr 7, Gr 9, Gr 12, Gr 16, Gr 17.

Size: OD 2.0-219 mm × Wall 0.3-12mm × Length ≤ 18000 mm.

Titanium Fasteners

One of our top products is the high-strength standard fasteners from GB, ISO, DIN, ANSI, ASME to JIS standard which are widely used in petroleum, metallurgy, chemical, pharmacy, marine engineering, racing car, motorcycle, bicycle, yacht, outdoor camping and sports equipment. All the specification below represent the most typical and popular size supplied to European market. Besides that, we also accept tailor-made fasteners according to your drawing .

One of unparalleled advantage is about 90% of the titanium bars, wires, sheets use to make these fasteners was manufactured by Yi Heng itself ,that greatly enhanced the the controllability, taceability and reliablility of the quality of the fasteners.

Nowadays, titanium fasteners was also available in different colors: red, yellow, blue, purple, green.

Titanium forging parts

Titanium forged products include blocks, bars, shafts, disks, hubs, forged rings, flanges, rings, seamless rolled rings, seamless contoured rolled rings, there forging parts often used due its strength and corrosion resistance, as well as being the most bio-compatible of all metals.

Standars:

Forged titanium part often requests do not follow common standards but are made to fit customer requirements. ShaanXi will work according to customers’ property requirements and forging needs. Yi Heng is able to offer titanium forging services to these common standards: ASTM B381, SAE AMS4928, SAE AMS4931, SAE AMS4911, SAE AMS4921.

How we do our work:

Our capabilities include 2500 and 4500 tons of hydraulic press, 4 sets of pneumatic forging hammer.

ShaanXi perform most rigorous Nondestructive Testing (NDT) for each single forging piece ultrasonic and liquid penetrant.

Titanium for civil use

Cookware

Why titanium cookware?

Titanium is 45% lighter than steel and stronger than aluminum. It is also resistant to corrosion and offers great durability. It is ideal for the construction of cookware: it is not reactive, durable, lighter and easier to clean.

It is a metal worldwide recognized as healthy and widely used in medicine because it does not contain heavy metals that can cause health problems. After prolonged use of the products, an oxide film forms on the surface of the titanium which helps to suppress the growth of bacteria.

After decades of hard work, our team has successfully developed the gold and titanium nanotechnology that has conquered the problem of scratching on the surface of cookware. Also, from the "lotus leaf effect", the pan is physically non-stick, giving you a smooth cooking experience. It is resistant to acids and limes and antioxidant so that the original flavor of the food is preserved to the maximum.

Deriving from “lotus leaf effect”, the pan is physically non-stick wich steadly bring you smooth kitchen experience. Super hardness enable the pan nofear of scratch, acid and alkali-resistant, no rust, original flavour of the food is reserved in máximum. Easier to handle with lighter wigth les tan 1.0 Kg. wall thickness ranged 1.20-1.50 mm.

Download our New Brochure

Discover the most current cookware :

• Sauce Pan

• Frying Pan

• Soup Pot

• Milk Pot

DOWNLOAD